Special Price for Children Indoor Amusement Area Climbing Wall Game Export to Mecca

Special Price for Children Indoor Amusement Area Climbing Wall Game Export to Mecca Detail:

Children Indoor Amusement Area Climbing Wall Game

| Item Name: | Children Indoor Amusement Area Climbing Wall Game |

|

Size (cm): |

OEM |

|

Certificates: |

CE,ISO14001, ISO18000, ISO9001, GS Certificate from TUV Company of Germany |

|

Material: |

A. Plastic parts: Imported LLDPE from Korea

B. Post: National standard galvanized steel pipe C. Metals: Galvanized Different material is available at your demand. |

|

Advantage: |

a.Anti-UV

b.Anti-static c.Security d.Environmental protection e.Color is not easy to fade |

|

Installation: |

a.Professional CAD instruction ,assembly procedure and project case .

b.can provide the professional oversea assembly engineers |

|

Package: |

Plastic parts: bubble bag and pp film; Metal parts: cotton and pp film

Special packaging is available. |

|

Warranty: |

1 year. |

Product detail pictures:

Related Product Guide:

How to Fix an Inflatable Water Slide: The Four Most Common Problems

Kids Indoor Play Equipment That Grows With the Kids

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for Special Price for Children Indoor Amusement Area Climbing Wall Game Export to Mecca, The product will supply to all over the world, such as: Peru , Switzerland , Angola , "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, You should contact with us now!

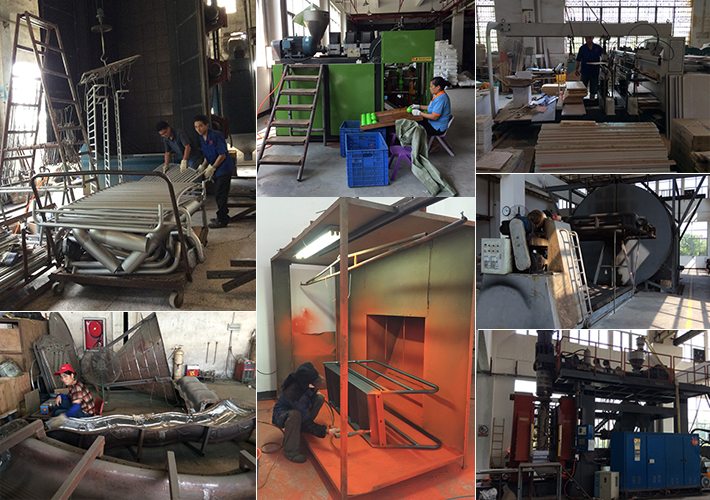

Established in 2003, Mutong is a comprehensive amusement equipment enterprise which focus on developing, designing, manufacturing, supplying and installing indoor and outdoor recreation equipments.

After more than 15 years developing, now MUTONG owns production base with area more than 10,000M2.

Our service:

1,Theme Children park overall plan:We provide service for real estate, kindergartens, streets, communities, parks, hotels, tourist resorts, water parks and all kinds of theme parks all over the world, including project designing, equipments producing and installation.

2,Outdoor playground equipments customized service:Parent-child playground, Company League- building playground.

3,Professional customized slides:We offer customized slides with material stainless steel, fiberglass, plastic, PE and wooden.

4,Indoor playground design:Indoor playground overall plan, product sales and installation.

5,Water park equipments:Water park slides, water splash pads, water features, water sprayers including design, sales, manufacture and installation.

Our advantages:

-Factory directly price

-More than 16 years manufacture experience

- CE, ISO9001:2008,ISO14001,OHSAS18001 standards

- 56+ Countries

- Dedicated Product R&D center

Our product series: Water park equipments; outdoor playground equipments; indoor plaground equipments; fitness equipments; wooden playground equipments etc.

Our certificates:

How to Make a Concrete Stamp Using PMC-780

Contents:

0:41 – Stone Paver Model Preparation

1:33 – Stone Paver Layout

3:32 – Making the Mold Box

4:46 – Creating Artificial Grout Line

6:12 – Making Handling Straps

7:15 – Mixing and Pouring PMC-780 Mold Rubber

9:06 – Demold

PMC-780 is a high performance urethane rubber that offers exceptional strength, durability and abrasion resistance.

Advantages of Stamping Concrete:

* Limitless design options

* Can be made to look like brick, stone, wood and more

* Stamp concrete indoors or out

* Lower labor and material cost

* Complete any project in a fraction of the time

* Lasting Durability: Concrete lasts for years and requires low mainenence

Stone Paver Model Preparation (0:41)

Melamine board will be used as the base. Our model is a concrete stone paver. Stone paver dimensions: 12″x12″x1″ (30.5cm x 30.5cm x 2.5cm). Four pavers will be used to create the model. Sonite Wax will be used to seal the stone paver. Sonite Wax is applied over entire face surface of the paver with a brush. Sealing is required to prevent adhesion during the mold making process. The process is repeated for the other pavers.

Stone Paver Layout (1:33)

Place the first paver a few inches from the edge of the baseboard. A second paver is placed with a 1/4″ (0.6cm) gap in between to represent the grout line. The last two pavers are offset from the first row. A 1/4″ grout line is maintained throughout the pattern. Paint sticks are used as spacers for creating the artificial grout lines. A steel square (right angle) is used to square the pavers. A pencil is used to create an outline of the pavers. The pencil outline will be used as a guideline when gluing the pavers to the baseboard. Hot-melt glue is applied to the inside perimeter of the outline. The glue holds the pavers in place to ensure proper placement when molding. Process is repeated for the other three pavers. Paint sticks are placed around the paver perimeter to represent outside grout line. Glue is used to adhere paint sticks together.

Making the Mold Box (3:32)

To construct the mold walls, measurements are taken from the outside edges. Melamine board is cut to size and will be used to construct the mold box walls. Remove all paint sticks. Place mold box walls into position. A 1/4″ grout line is maintained between pavers and around the perimeter. Walls are secured with drywall screws. Paint sticks are placed around the mold box perimeter to ensure proper grout spacing.

Creating Artificial Grout Line (4:46)

Sculptex non-sulfur based clay will be used to fill in the grout cavity. Sculptex is easily cut into 1/4″ sefments with a knife. The clay is used to fill in the caity to create an artificial grout line. Remove spacers as needed. Clay is also placed along mold box walls. A chisel is used to create a “pointed grout” line in the clay. A chip brush is trimmed to stiffen the bristles. The brush is used to create a sanded grout texture. Hot-melt glue is applied to all seams of the mold box, preventing any leaks of mold rubber. Universal Mold Release is applied to all surfaces to prevent adhesion of the mold rubber.

Making Handling Straps (6:12)

Nylon webbing will be used to form straps that will be incorporated into the stamp. Two sections of nylon webbing are cut to approximately 14″ (35.6 cm) in length. Webbing is looped to form a handle. The loop is held in place with a staple. Gallon containers will support the bridge in which the handles are suspended. Two paint sticks are glued together and will act as a bridge to support the webbing. The wood bridge is placed in the center of the mold box. Webbing is suspended 1/2″ (1.3cm) above the model.

Mixing and Pouring PMC-780 Mold Rubber (7:15)

PMC-780 Urethane Rubber Compound, mix ratio 2A:1B by volume. Part B is pre-mixed before using. SO-Strong pigments were used to transform the PMC-780 (amber in color) into an opaque orange. SO-Strong White is added to Part B, this will make the translucent rubber opaque. Color tint is blended into Part B. SO-Strong Orange is added to Part B and mixed. Part A is dispensed into a large mixing bucket. Dispense the pigmented Part B into Part A. Mix thoroughly for three minutes. Scrape sides and bottom of mixing container to ensure a proper mix of materials. Slowly pour the rubber into the mold box. Rubber should level off at least 1/2″ over the highest point of the model’s surface. Adjustments are made to ensure the web handles are encapsulated in the rubber and not touching the face of the model. Let the rubber cure for 48 hours at room temperature (73°F/23°C) before demolding.

Demold (9:06)

A scraper is used to loosen the rubber from the mold box walls. Fully cured rubber is ready to demold. PMC-780 picks up all the detail from the original stone paver. PMC-780 rubber is durable yet flexible.

Make It Now! with Smooth-On

https://www.smooth-on.com/

https://www.facebook.com/SmoothOn

https://twitter.com/SmoothOn

https://www.google.com/+smoothon

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

![WT0{ZSFM{5Z~@}D4JG$]GZ3](http://www.mutongplay.com/uploads/WT0ZSFM5Z@D4JGGZ3.png)