15 Years Manufacturer Water Park Spray Gun for Kids for Haiti Factories

15 Years Manufacturer Water Park Spray Gun for Kids for Haiti Factories Detail:

Water Park Spray Gun for Kids

|

Item Name: |

Water Park Spray Gun for Kids |

|

Size (cm): |

OEM |

|

Certificates: |

CE,ISO14001, ISO18000, ISO9001, GS Certificate from TUV Company of Germany |

| Material: | A. Plastic parts: Imported LLDPE from Korea

B. Post: National standard galvanized steel pipe C. Metals: Galvanized Different material is available at your demand. |

| Advantage: | a.Anti-UV

b.Anti-static c.Security d.Environmental protection e.Color is not easy to fade |

| Installation: | a.Professional CAD instruction ,assembly procedure and project case . b.can provide the professional oversea assembly engineers |

| Package: | Plastic parts: bubble bag and pp film; Metal parts: cotton and pp film

Special packaging is available. |

|

Warranty: |

1 year. |

Product detail pictures:

Related Product Guide:

How to Fix an Inflatable Water Slide: The Four Most Common Problems

5 Craziest and Best Water Slides to Enjoy This Summer

"Sincerity, Innovation, Rigorousness, and Efficiency" would be the persistent conception of our corporation to the long-term to establish collectively with customers for mutual reciprocity and mutual benefit for 15 Years Manufacturer Water Park Spray Gun for Kids for Haiti Factories, The product will supply to all over the world, such as: Comoros , Honduras , Sheffield , To make every client satisfied with us and achieve win-win success, we will continue to try our best to serve and satisfy you! Sincerely looking forward to cooperating with more overseas customers based on mutual benefits and great future business. Thank you.

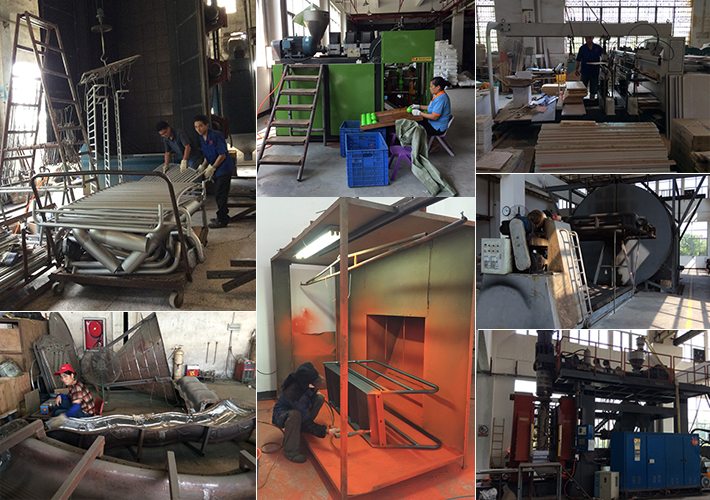

Established in 2003, Mutong is a comprehensive amusement equipment enterprise which focus on developing, designing, manufacturing, supplying and installing indoor and outdoor recreation equipments.

After more than 15 years developing, now MUTONG owns production base with area more than 10,000M2.

Our service:

1,Theme Children park overall plan:We provide service for real estate, kindergartens, streets, communities, parks, hotels, tourist resorts, water parks and all kinds of theme parks all over the world, including project designing, equipments producing and installation.

2,Outdoor playground equipments customized service:Parent-child playground, Company League- building playground.

3,Professional customized slides:We offer customized slides with material stainless steel, fiberglass, plastic, PE and wooden.

4,Indoor playground design:Indoor playground overall plan, product sales and installation.

5,Water park equipments:Water park slides, water splash pads, water features, water sprayers including design, sales, manufacture and installation.

Our advantages:

-Factory directly price

-More than 16 years manufacture experience

- CE, ISO9001:2008,ISO14001,OHSAS18001 standards

- 56+ Countries

- Dedicated Product R&D center

Our product series: Water park equipments; outdoor playground equipments; indoor plaground equipments; fitness equipments; wooden playground equipments etc.

Our certificates:

inline capping machine for round jar with conveyor belt adhesive labeller línea máquina taponadora

https://www.chinesepacker.com

Any questions,feel free to contact me.

Email: sales@chinesepacker.com Skype:zhang.tracy6 Tel:0086-13262514660

Click here to subscribe us

https://www.youtube.com/channel/UCo4XjYB_mRONyQKah8jbjVw

Introduction:

Our new Automatic Capping Machine lid-revolver style has been improved recently by our company. The machine’s appearance is artistic and scholar. It’s quick lid-revolving speed, high conformity rate makes it suitable for different bottle shapes. The Lid-revolving is suitable for bottles and caps of the foodstuff, pharmacy, daily chemical industry, pesticide, cosmetics, etc. The four units of speed-adjustable motors are separately used in lid-feeding, bottle-clamping, conveying and lid-revolving, the machine has a high automation degree, good steadiness, convenient adjustment, changing bottle sizes or lid, needn’t any parts, only need some adjustments (for example, link with the lid-feeder, may automatically feed lids)

Application:

Suitable for different size of all kinds of bottle.

It is used in PET bottle, plastic bottle, glass bottle, Metal bottle etc.

Features:

1. Capping speed up to 150 CPM

2. One button to adjust height

3. Wide applicability for various caps and bottles

4. Auto stop and alarm when lack of cap

5. Stainless steel frame

6. No-tool adjustment

7. Choice of various types of cap feeders

Characters:

This automatic inline capping machine has four speed-adjustable motors which separately used in lid-arranging, sleeve lid, lid-capping and conveying,in the capping process can be automatic arrange lid, automatic sleeve lid, automatic capping.As the machine use bottle-clamping belt to ensure the bottles not fall down when lid sleeving and capping, this capping machine has simple structure, good steadiness, adjust convenient, no need to change spare parts,only need some adjustment. Suits for the round shape,rectangular flat shaped and irregular shape bottle capping for foodstuff,pharmacy,cosmetic,daily chemical,fertilizer and chemical industry.

1.Adopt agile module combination, new ideal design, suit to various bottle and cap-rotating.

2.Needn’t change parts, easily adjust is ok.

3.Easy operation and convenient for maintenance.

4. Capping system consist of first rotating and re-rotating the degree of moment may be adjusted singly. Ensure that will be tight. The screw capper has clutch to avoid the cap over-rotating.

5.Bottle nipping and annular belt structure, Good effect for some bottles erecting unsteadily.

6.Cap arranging part, conveying part, cap-rotating, belt for bottle, nipping, all of speed can be governing separately, which is more utility.

7.Choosing automatic cap-sender and cap hopper

8.The plastic bottle cap sealing machine is designed according to requirements of GMP.

Main technical parameters:

Production Capacity 50-150 bottles/min

lid sizes 15-70mm

bottle diameter Φ 35-140mm

bottle height 30-380mm

working air pressure 3-5kg/m3

contour sizes 2000*870*1500mm

Production Capacity 150 bottles/min

About Packing:

To ensure our service quality, we will execute the following packaging standards in delivery:

1.All the products before delivery should be tested by assemble and debugging engineer, wiped up and cleaned, then wrapped by stretch film to protect it from moist. The precision part need to flexible package.

2.In addition, without standard tools, manual and other documents, and allow ex-factory confirmation sheet, the machine cannot leave factory All the products will be packed in wooden case. The exported products use plywood case to pack. The foot margin of equipment fixed tightly to make the machine can experience loading and uploading, the upward mark will be posted on the wooden case.

Pre-sales:

According to client specific labeling requirement, supply reasonable machine sketch map,quotation and similar video for client ref first.

During Sales:

1) Depends on client products and labeling position, made reasonable reform base on the standard machine.

2) Repeat 20 ongoing hours testing equipment operation stability .

3) Execute GMP certification for the equipment and materials used in the production process requirement and specification strictly.

After sale:

1. Range experienced senior engineer come to client company for installation .

2. Supply systematic operation training for client workers.

3. Guarantees all equipment (except human factors) within one year, lifetime maintenance sevices.

4. After client use the machine for several years, we can provide a detailed refurbishment program, the original equipment and replacement of hardware and software upgrades.

5. If quality problems arise, the supplier provide technical support and timely supply wearing parts.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!

![WT0{ZSFM{5Z~@}D4JG$]GZ3](http://www.mutongplay.com/uploads/WT0ZSFM5Z@D4JGGZ3.png)