Low MOQ for Children Outdoor Climbing Structure for Outdoor Playground for Swedish Importers

Low MOQ for Children Outdoor Climbing Structure for Outdoor Playground for Swedish Importers Detail:

Children Outdoor Climbing Structure for Outdoor Playground

| Item Name: | Children Outdoor Climbing Structure for Outdoor Playground |

| Size (cm): | OEM |

| Certificates: | CE,ISO14001, ISO18000, ISO9001, GS Certificate from TUV Company of Germany |

| Material: | A. Plastic parts: Imported LLDPE from Korea B. Post: National standard galvanized steel pipe

C. Metals: Galvanized Different material is available at your demand. |

| Advantage: | a.Anti-UV b.Anti-static

c.Security d.Environmental protection e.Color is not easy to fade |

| Installation: | a.Professional CAD instruction ,assembly procedure and project case .

b.can provide the professional oversea assembly engineers |

| Package: | Plastic parts: bubble bag and pp film; Metal parts: cotton and pp film Special packaging is available. |

|

Warranty: |

1 year. |

Product detail pictures:

Related Product Guide:

Outdoor Playground Equipment – 5 Safety Tips to a Better Play Experience

How to Fix an Inflatable Water Slide: The Four Most Common Problems

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for Low MOQ for Children Outdoor Climbing Structure for Outdoor Playground for Swedish Importers, The product will supply to all over the world, such as: Israel , Latvia , Swaziland , Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery. Our products are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

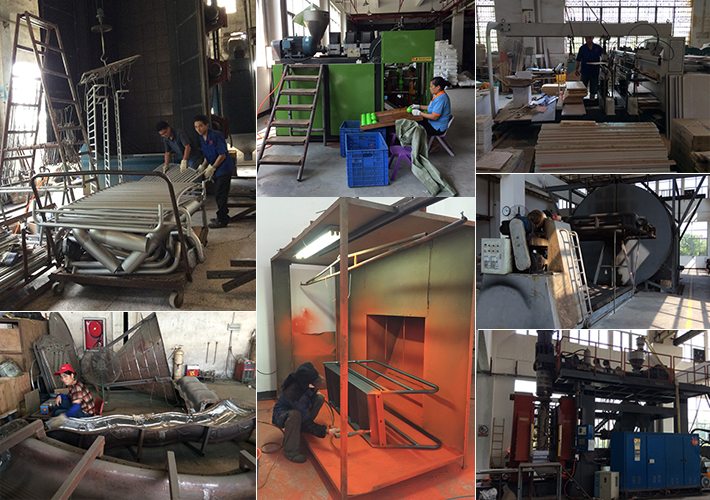

Established in 2003, Mutong is a comprehensive amusement equipment enterprise which focus on developing, designing, manufacturing, supplying and installing indoor and outdoor recreation equipments.

After more than 15 years developing, now MUTONG owns production base with area more than 10,000M2.

Our service:

1,Theme Children park overall plan:We provide service for real estate, kindergartens, streets, communities, parks, hotels, tourist resorts, water parks and all kinds of theme parks all over the world, including project designing, equipments producing and installation.

2,Outdoor playground equipments customized service:Parent-child playground, Company League- building playground.

3,Professional customized slides:We offer customized slides with material stainless steel, fiberglass, plastic, PE and wooden.

4,Indoor playground design:Indoor playground overall plan, product sales and installation.

5,Water park equipments:Water park slides, water splash pads, water features, water sprayers including design, sales, manufacture and installation.

Our advantages:

-Factory directly price

-More than 16 years manufacture experience

- CE, ISO9001:2008,ISO14001,OHSAS18001 standards

- 56+ Countries

- Dedicated Product R&D center

Our product series: Water park equipments; outdoor playground equipments; indoor plaground equipments; fitness equipments; wooden playground equipments etc.

Our certificates:

The major thrust of EDCI Clean Energy Solutions is the conversion of waste and other carbonaceous materials into synthesis gas, liquid fuels and/or electricity. Depending upon the specific solution needed, EDCI works to establish a sound partnership that provides the right combination of cutting-edge technologies and expert project management.

The advantages of using EDCI Clean Energy Solutions to convert carbonaceous materials and hydrocarbons into synthesis gas, liquid fuels and/or electricity are that:

- Nothing hazardous ever goes into the ground, and practically no pollutants go into the air (emissions are well below all California EPA requirements). Through a proprietary “closed loop” system using super-low NOx burners and advanced thermal distillation technology developed by ACTi, our processes provide clean energy solutions that are more efficient and environmentally-friendly than any competitor’s.

- Processing of variable waste/organic streams through standard and proprietary processes (e.g. automated recycling of metals, autoclaving of municipal solid waste, etc.), provide for a much greater efficiency in the clean energy process, including the storage of gasification feedstock and produced fuels, as well as the concurrent gasification of multiple carbonaceous materials (e.g. coal, municipal solid waste, agricultural and animal waste, sewage sludge, used tires, waste plastics, medical waste, etc.)

- Outputs are (1) synthesis gas, or syn-gas (CO+H2), which is either chemically converted to synthetic carbon-based fuels, or combusted in engines or turbines to generate electrical power using other available technologies, and (2) residue (i.e. any dirt, rocks, glass or ash not consumed in the gasification process) which can be used as a fertilizer additive, or converted into a superior concrete-like building material by mixing it with a geopolymer chemical binder.

- Synthetic sulfur-free # 2 diesel fuel, other liquid fuels including ethanol, and/or electricity is produced below current market value, and with the capacity to be generated in different proportions and times depending upon specific energy needs.

- Modular engineering, built-in redundancy of key modules, and common maintenance and replacement parts, limit down-time and allow nearly 100% energy production capacity.

EDCI Clean Energy Solutions for municipal solid waste involve initial processing with proprietary technologies from trusted strategic partners to sterilize the waste stream while separating recyclable ferrous and non-ferrous metals, resulting in a sterile and automatically sorted homogeneous feedstock for subsequent gasification.

Following initial processing as needed for the specific carbonaceous material at hand, EDCI Clean Energy Solutions further utilize proprietary gasification and gas-to-liquefaction technologies from ACTi. While many new technologies in the recycling field have emerged with increases in the cost of petroleum products and concerns over global warming, ACTi processes by comparison are considered more versatile in that they convert numerous waste streams at a much lower capital and operating cost. Notably, ACTi processes also have direct commercial and operating experience with tires, medical waste, agricultural waste, MSW, coal, and waste plastic.

ACTi manufactures an advanced commercial thermal distillation system (see figure) to convert various waste materials as noted to highly valuable commodities. ACTi’s thermal distillation process was designed to specifically address the short-comings of previous technologies and involves the thermal decomposition of organic matter at temperatures sufficient to gasify organic material under a slight vacuum and in the absence of oxygen. As the temperature increases, vapors flow out of the reaction chamber and are further processed into syn-gas which then undergoes a gas-to-liquefaction process that creates synthetic carbon-based fuel as a clean energy resource. Alternatively, the cleaned syn-gas produced by the system can be combusted directly in a turbine or engine to produce electricity.

ACTi’s advanced recycling technology consists of a “closed loop” reaction chamber heated with super-low NOx burners. ACTi’s patented super-low NOx burner system is considered the most efficient in the world for low NOx emissions. The entire system is designed so that no raw gases can be released to the atmosphere.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

![WT0{ZSFM{5Z~@}D4JG$]GZ3](http://www.mutongplay.com/uploads/WT0ZSFM5Z@D4JGGZ3.png)