Good Quality Children Amusement Equipment Outdoor Playground Plastic Slide for Vietnam Manufacturers

Good Quality Children Amusement Equipment Outdoor Playground Plastic Slide for Vietnam Manufacturers Detail:

Children Amusement Equipment Outdoor Playground Plastic Slide

| Item Name: | Children Amusement Equipment Outdoor Playground Plastic Slide |

|

Size (cm): |

OEM |

|

Certificates: |

CE,ISO14001, ISO18000, ISO9001, GS Certificate from TUV Company of Germany |

|

Material: |

A. Plastic parts: Imported LLDPE from KoreaB. Post: National standard galvanized steel pipeC. Metals: Galvanized

Different material is available at your demand. |

|

Advantage: |

a.Anti-UVb.Anti-static

c.Security d.Environmental protection e.Color is not easy to fade |

|

Installation: |

a.Professional CAD instruction ,assembly procedure and project case .b.can provide the professional oversea assembly engineers |

|

Package: |

Plastic parts: bubble bag and pp film; Metal parts: cotton and pp film

Special packaging is available. |

|

Warranty: |

1 year. |

Product detail pictures:

Related Product Guide:

Outdoor Playground Equipment – 5 Safety Tips to a Better Play Experience

Kids Indoor Play Equipment That Grows With the Kids

We can easily usually fulfill our respected customers with our very good top quality, very good price tag and excellent support due to we have been more expert and much more hard-working and do it in cost-effective way for Good Quality Children Amusement Equipment Outdoor Playground Plastic Slide for Vietnam Manufacturers, The product will supply to all over the world, such as: British , Canada , Marseille , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

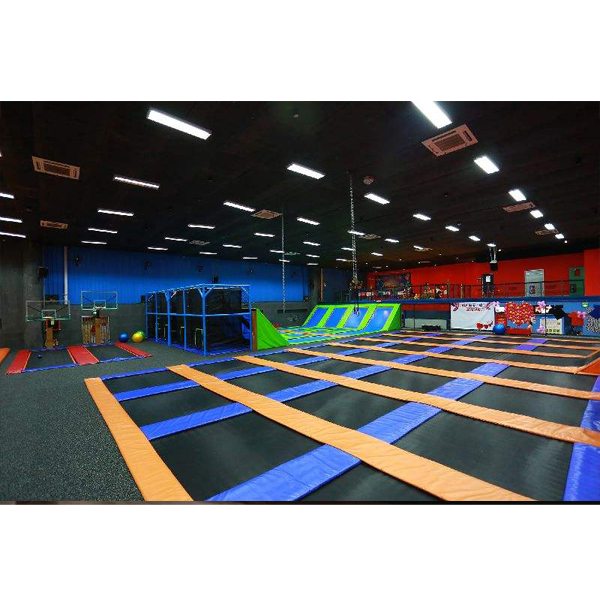

Established in 2003, Mutong is a comprehensive amusement equipment enterprise which focus on developing, designing, manufacturing, supplying and installing indoor and outdoor recreation equipments.

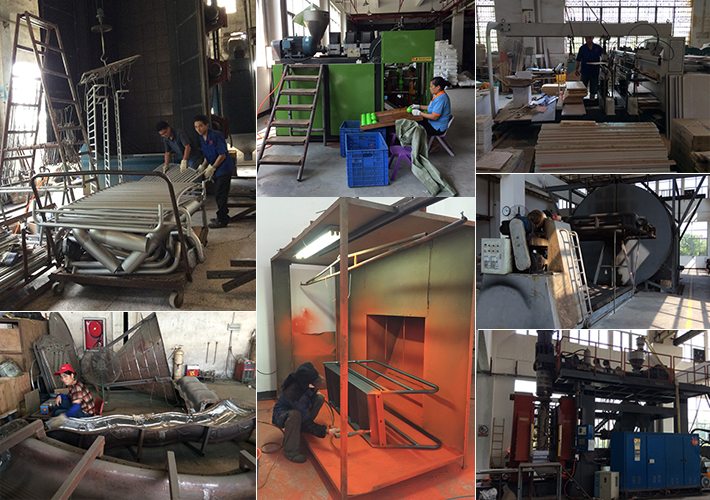

After more than 15 years developing, now MUTONG owns production base with area more than 10,000M2.

Our service:

1,Theme Children park overall plan:We provide service for real estate, kindergartens, streets, communities, parks, hotels, tourist resorts, water parks and all kinds of theme parks all over the world, including project designing, equipments producing and installation.

2,Outdoor playground equipments customized service:Parent-child playground, Company League- building playground.

3,Professional customized slides:We offer customized slides with material stainless steel, fiberglass, plastic, PE and wooden.

4,Indoor playground design:Indoor playground overall plan, product sales and installation.

5,Water park equipments:Water park slides, water splash pads, water features, water sprayers including design, sales, manufacture and installation.

Our advantages:

-Factory directly price

-More than 16 years manufacture experience

- CE, ISO9001:2008,ISO14001,OHSAS18001 standards

- 56+ Countries

- Dedicated Product R&D center

Our product series: Water park equipments; outdoor playground equipments; indoor plaground equipments; fitness equipments; wooden playground equipments etc.

Our certificates:

Cardboard boxes come in a wide variety of sizes shapes and colors but most share three basic structural components. One wavy sheet of paper called a flute, that is sandwiched between two flat sheets called liners. Together they form what’s called a corrugated board. Production starts with a massive role of partially recycled paper. The width of the paper varies depending on the size of the boxes their making. Several feeds a machine called the corrugator. The machine presses the paper between two ridged rollers and is blasted with hot steam. This shapes the waves of the flute. Another roller applies glue to one side of the flute. The glues main ingredients are water and starch, which won’t contaminate fresh produce the boxes may later contain. Next the machine adheres one liner sheet and then the other. The waves create an air cushion between the flute and the liners, strengthening the board. For added strength some boxes have a double liner. https://www.interplas.com/packaging-boxes/BXHDDW Two flutes and three liners. The flutes may vary in thickness for more cushioning. The factory uses partially recycled paper for the flutes, because it is more malleable than non recycled paper. A razor thin circular saw trims each side. The corrugator machine then cuts the board up to nine times depending on the size of the box they are producing. The corrugator final function is to separate the boards into layers using flexible tongs called fingers. Workers do a quality control check before sending the boards off for printing. The next machine stacks the boards into piles of between twenty five and eighty depending on their thickness. This machine also feeds one board at a time to the upcoming equipment. It does at lightening speed at a rate of up to eight thousand boards per hour.

First the trimmer perforates the boards to create flaps and handles. Rubber sponges cushion the blades so that they only cut the parts they’re suppose to. During the trimming a press condenses the boxes overlapping panels to level out their thickness. Workers usually cut out the sponges by hand to make sure they fit snugly around the blades. The trimmer runs at a speed of eight kilometers per hour. Processing up to ninety boxes a minute. Workers send the cut offs back to the paper mill to be recycled as many as six times over.

A folding machine now bends them along score lines that the corrugator made earlier. It then applies cold glue to the sections that will join together to form the box. Hot glue on the cardboard is wax coated. The next machine folds over the glued sections. They are invisible once the box is finished. Another machine stacks the boxes in piles. A separator arm moves the boxes to trays called skids, for shipping.

The printing of the boxes began in the factories ink kitchen. A computer guided dispenser squirts out different shades of ink following a precise recipe to create a particular color one of five thousand in the pallet. One pail holds about twenty kilograms of printing ink. Enough for about two thousand boxes, depending on the coverage needed. The factory uses water based ink, because it dries instantly. The printing press applies the ink to the boards one color group at a time, through four consecutive stations. This factory uses a flexographic printing system. A process that can print drawings and illustrations. Some companies use a lithographic press which can also print photographs.

Back on the trimming line, more complicated types of box flaps and handles require what is called a flatbed trimmer. It holds the boards in place with suction while making intricate perforations. After removing the trimmed bits workers give the boxes one last quality check. The they stack them and send them off to the warehouse

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

![WT0{ZSFM{5Z~@}D4JG$]GZ3](http://www.mutongplay.com/uploads/WT0ZSFM5Z@D4JGGZ3.png)